The Science Behind Anaerobic Digestion and Biomass

Farming has always been about working with nature. Every day, you produce organic waste—manure, crop residues, even food scraps from your on-farm kitchen. Rather than seeing these as just leftovers that need disposal, modern farming shows us that they can become sources of renewable energy and valuable soil improvement. Two systems stand out in today’s sustainable agriculture: anaerobic digestion and biomass conversion.

This article digs into the simple science behind these methods. It explains how tiny microorganisms work to break down waste in a controlled environment and how you can harness that energy to heat your barns, power engines, or even generate electricity. We’ll also cover how the leftover material can boost your soil’s fertility. By the end of our guide, you’ll know what steps you can take to start a project on your farm.

1. Introduction: Turning Waste into Opportunity

Organic waste is something every farm produces—manure, leftover crops, and plant residues all add up. Traditionally, this waste required careful disposal, and it sometimes piled up to become a problem. Today, however, technology and nature offer ways to recycle these materials, reducing costs and lessening your farm’s environmental impact. Through anaerobic digestion and biomass energy techniques, what was once a challenge can become an opportunity.

In simple terms, anaerobic digestion is a controlled process where microorganisms break down organic waste in the absence of oxygen. Biomass, on the other hand, refers to any organic material that comes from plants or animals. When these two ideas come together, you have a system where your waste not only helps power your operations but also becomes a beneficial fertilizer, helping your crops grow better.

2. What Is Anaerobic Digestion?

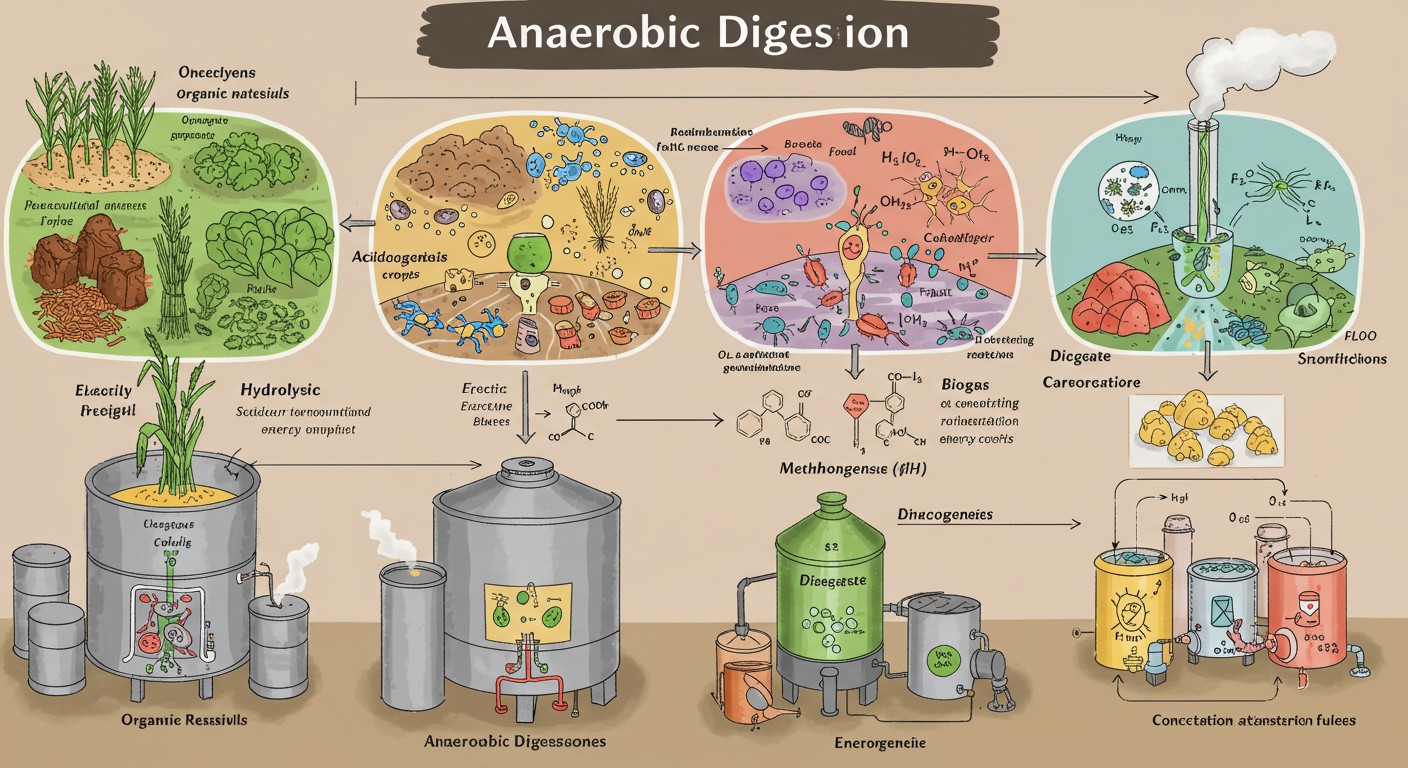

Anaerobic digestion is a natural process that happens in an oxygen-free environment. Inside a sealed container called a digester, tiny living organisms—mostly bacteria—break down organic matter. This process produces biogas and a useful byproduct known as digestate. Here’s how it works in everyday language:

- Collection and Mixing: Feedstock (such as manure, plant waste, or food scraps) is mixed with water. This mixture, called slurry, gives the microorganisms a good environment to do their work.

- The Sealed Digester: The slurry is placed into a sealed tank or digester. Because the process happens without oxygen (anaerobic), the tank must be airtight.

- Microorganisms at Work: In a matter of weeks, microbes start breaking down the waste. As they do so, they produce biogas. This gas is mainly methane, which is a renewable fuel.

- Collecting the Biogas and Digestate: The biogas rises to the top of the tank and is collected through pipes. You can use it for cooking, heating, or running small engines. The leftover material, called digestate, is rich in nutrients and can be used as a fertilizer on your fields.

Anaerobic digestion is not only a waste management tool—it also helps your farm save money on fuel and improve soil fertility at the same time.

3. The Simple Science Behind Anaerobic Digestion

Let’s break down the science behind anaerobic digestion in everyday terms:

- Role of Microorganisms: Thousands of tiny organisms work inside the digester. In the absence of oxygen, they use the waste as food. As they digest the material, they produce heat, gas, and a nutrient-rich liquid. This process might sound complex, but think of it as a natural “cooking” process where low heat and time transform waste into something useful.

- Chemical Reactions Made Simple: When bacteria break down the organic matter, the main chemical change is the transformation of complex material like carbohydrates and proteins into simpler compounds. The key product is methane (CH₄) and carbon dioxide (CO₂). In simple chemical terms: Organic matter + Microorganisms → Methane + Carbon Dioxide + Digestate This reaction releases energy that you capture as biogas.

- Importance of a Controlled Environment: Anaerobic digestion works best when the temperature and pH (how acidic or basic the slurry is) stay within certain ranges. Most systems work best at temperatures between 30° and 40°C (86–104°F). Keeping the process inside a sealed, stable environment allows the microbes to work efficiently.

By controlling environmental factors such as temperature and the balance of water to solids, you ensure that the digestion process happens quickly and produces a steady supply of biogas and a high-quality fertilizer.

4. What Is Biomass?

Biomass is simply any organic material that comes from plants or animals. On your farm, biomass can be manure, crop residues, or even dedicated energy crops grown specifically to produce fuel. In short, if it grows or is produced by plants and animals, it can be called biomass.

Biomass contains stored energy—energy that once came from the sun. By using processes such as anaerobic digestion or burning biomass directly (in specially designed equipment), you can release that stored energy to help power your farm’s operations. Turning biomass into energy is part of a larger move toward sustainable and renewable energy systems.

5. How Do Anaerobic Digestion and Biomass Work Together?

These two processes are closely linked. Here’s how they connect:

- Feedstock Source: The same materials that create biomass—like manure and crop residues—fuel anaerobic digestion. When you feed these materials into a digester, you are turning biomass into biogas and digestate.

- Energy Production: Instead of burning biomass directly (which can release smoke and pollutants), anaerobic digestion captures the energy inside the material in the form of biogas. This biogas can be burned cleanly for energy, reducing your reliance on fossil fuels.

- Nutrient Recycling: After biogas extraction, the digestate left over is rich in nutrients. You can return this digestate to the fields as natural fertilizer, thus completing a cycle that boosts soil quality and crop production.

In this way, your farm can move toward a system where waste turns into energy and improved soil—all by making smart use of biomass you already have.

6. Benefits of Converting Biomass into Energy

There are many reasons to consider converting biomass into energy. Here are some of the key benefits:

A. Renewable Energy Supply

- Cost Savings: Fuel prices can keep rising. By producing your own biogas, you reduce your dependence on purchased fuels like propane or diesel. The energy from biogas can be used for cooking, heating, or even small-scale power generation on your farm.

- Energy Independence: Having your own renewable energy source helps make your farm more self-reliant. If fuel supplies become unpredictable or expensive, you have a backup system in place.

B. Improved Waste Management

- Reduced Disposal Costs: Managing manure and other waste can be costly and sometimes regulated by local laws. Anaerobic digestion greatly reduces the volume of waste while transforming it into useful products.

- Lower Odors and Pollution: When waste decomposes in a controlled digester, it produces fewer odors and minimizes the risk of water and air pollution—a common worry with exposed manure piles.

C. Enhanced Soil Fertility

- Nutrient-Rich Digestate: After biogas is captured, what’s left may be spread over your fields. This digestate is rich in essential nutrients like nitrogen, phosphorus, and potassium, making it a natural fertilizer that helps improve crop yields.

- Long-Term Soil Health: Regular application of digestate or compost helps build better soil structure, enhancing its ability to hold water and nutrients.

D. Environmental Benefits

- Lower Greenhouse Gas Emissions: Methane is a potent greenhouse gas. By capturing and using it as fuel, you prevent it from escaping into the atmosphere. This helps reduce your overall environmental impact.

- Sustainable Farming Practices: Using renewable energy and recycling waste helps reduce your farm’s carbon footprint. It positions your operation as environmentally responsible and may also qualify you for local grants or incentives.

7. Practical Steps to Implement Anaerobic Digestion and Biomass Conversion on Your Farm

Step 1: Evaluate Your Farm’s Waste Resources

Action Points:

- Inventory Your Waste: Make a list of the different types of organic waste available—manure, crop residues, food leftovers, etc. Measure how much you produce on a daily or weekly basis.

- Determine Consistency: Assess how steady the supply of waste is. Year-round consistency makes it easier to run a continuous anaerobic digestion system.

Step 2: Decide on the Type of System You Need

Action Points:

- Pilot Project vs. Full Scale: If you’re new to these systems, start small. Many farms begin with a pilot digester, a smaller system that allows you to learn the process. Once you’re comfortable, you can expand.

- System Type: Options range from low-tech, DIY digesters made from repurposed materials (like large barrels or water tanks) to more commercial, professionally installed systems. Consider your budget and technical comfort level.

Step 3: Set Up a Digester

Action Points:

- Choose a Location: Pick a sheltered, accessible spot on your farm. A location that stays warm and is not exposed to the harshest weather usually works best.

- Gather Materials: You’ll need a sealed tank (the digester), pipes for gas collection, and safety valves. Consult local agricultural suppliers or engineers who specialize in biogas systems for guidance.

- Establish a Feed Routine: Plan how you will mix and pump your waste into the digester. A controlled feed ensures the system runs smoothly. For example, maintain a mixture of water and organic material that is not too thick or too runny.

Step 4: Monitor and Maintain Your Digester

Action Points:

- Regular Checks: In the early stages, inspect the system daily. Use tools like a thermometer and a pH meter to keep track of the internal conditions. Aim for a stable temperature and balanced pH to keep the microorganisms happy and working efficiently.

- Record Keeping: Keep a simple log of feed inputs, temperature, pH, and gas production. This record will help you spot trends and make necessary adjustments.

- Safety First: Ensure that all pipes, seals, and valves are leak-proof. Since biogas is flammable, proper ventilation and periodic checks are essential to avoid accidents.

Step 5: Use the Biogas and Digestate

Action Points:

- Energy Use: Once you have captured enough biogas, decide how to use it. Many farms install simple burners for cooking or heating barns. Others connect the gas to generators that produce electricity.

- Fertilizer Application: The digestate left in the digester can be separated into liquid and solid parts. The liquid is rich in nutrients and can be spread over your fields, while solids can be further composted if needed.

- Evaluate and Adjust: Over time, compare your energy savings and fertilizer value against your operating costs. Use these results to improve your process incrementally.

8. Challenges in the Process and How to Overcome Them

No system is perfect from day one. Here are common issues you might encounter and some ways to address them:

A. Feedstock Inconsistency

- The Issue: The quality and composition of your organic waste can change with the seasons, which can affect biogas production.

- What You Can Do: Mix different types of waste to keep the feedstock balanced. For instance, if you have a sudden spike of crop residue in the harvest season, balance it with steady manure inputs.

B. Temperature Fluctuations

- The Issue: In colder months, the digester might slow down because the microbes are less active.

- What You Can Do: Use insulation or mild heating methods to keep the digester within an optimal temperature range (around 30–40°C or 86–104°F).

C. Maintenance and Monitoring

- The Issue: The science behind these systems is simple, but it does require regular attention.

- What You Can Do: Establish a routine check for your digester. Involve family members or farm workers in basic training to look after the system. Keeping a log is essential to catch any early signs of trouble.

D. Initial Investment and Cost

- The Issue: Setting up an anaerobic digestion system can require a higher upfront investment compared to traditional waste management.

- What You Can Do: Look for government grants, local cooperatives, or cost-sharing programs that help farmers with renewable energy projects. Starting with a pilot system can also make the initial risk lower until you see the benefits.

9. Real-Life Farm Examples

Example 1: A Dairy Farm’s Journey

Farmer Bill has a medium-sized dairy farm and produces a steady flow of cow manure. Facing continually rising fuel costs, he wondered if he could reduce his reliance on purchased energy.

- What He Did: Bill began with a small pilot digester built from a repurposed water tank and a set of pipes for collecting biogas. He mixed cow manure with a little water each day and fed it into the system. For the first few weeks, he kept detailed records of the temperature and gas output.

- What Happened Next: After a few weeks, Bill noticed a steady production of biogas. He used the gas to heat his barn during cooler evenings, reducing his heating bills. The leftover digestate was spread over his fields, improving soil fertility and crop yield.

- Outcome: Bill’s small project not only saved him money but also showed him the potential rewards of scaling up the system in the future.

Example 2: A Vegetable Farm Embracing Biomass Energy

Farmer Lisa runs a vegetable farm with plenty of crop residues and a small amount of animal manure. Knowing that healthy soil is key to strong crops, she was keen on using every part of her waste effectively.

- What She Did: Lisa set up a composting area to handle crop residues but also tried a pilot anaerobic digester. She balanced her feedstock by mixing crop residues with manure, ensuring that the digester had the right moisture level.

- What Happened Next: Although her gas output was lower compared to a larger dairy system, she managed to produce enough biogas to run a small generator. This generator powered a pump for her irrigation system, reducing her electricity costs.

- Outcome: Lisa found that using her biomass for energy helped her farm become more sustainable and efficient. Moreover, the digestate further enriched her compost, boosting soil structure and water retention.

10. Financial and Environmental Advantages

In addition to reducing waste and providing energy, these systems offer multiple benefits that can make your farm more profitable and sustainable:

Economic Benefits

- Fuel Savings: By producing your own biogas, you can cut down on the rising costs of fossil fuels. The energy generated can power various farm activities, from heating to irrigation.

- Fertilizer Costs Reduced: The nutrient-rich digestate can replace or reduce the need for chemical fertilizers, keeping your input costs lower while improving soil health.

- Potential for Additional Income: Some farms have even explored selling excess biogas or digestate to neighbors or local cooperatives—a win for community-based energy and waste management.

Environmental Benefits

- Lower Greenhouse Gas Emissions: Capturing methane that would otherwise escape into the atmosphere helps reduce the overall greenhouse gas footprint of your farm.

- Improved Soil Health: With regular applications of digestate or compost, your soil becomes richer in organic matter. Healthier soil improves water retention and reduces erosion.

- Sustainable Farming Practices: Adopting renewable energy and waste recycling methods positions your farm as environmentally responsible. This can improve your farm’s reputation and open up opportunities for local grants or incentives related to sustainability.

11. Next Steps: Making the Transition on Your Farm

Implementing anaerobic digestion and biomass energy isn’t an overnight process—it requires careful planning and gradual implementation. Here’s a checklist to guide your next steps:

- Survey Your Waste: List out the types and volume of organic waste you produce. Identify the main sources—manure, crop residues, etc.—and evaluate their consistency over the year.

- Decide Between a Pilot or Full-Scale System: Start small if you’re new to the process. A pilot system gives you practical experience before scaling up.

- Budget and Research: Look into available grants or cost-sharing programs. Talk to local agricultural extension services or visit other farms that have installed similar systems.

- Design Your System: Decide on the system design (DIY or commercial) and choose the right size for your needs. Plan for necessary tools like pH meters, thermometers, and safety equipment.

- Implement and Monitor: Set up your pilot system, begin feeding it with a balanced mix of organic waste, and carefully record your observations. Adjust the feedstock, temperature, or mixing process as needed.

- Expand Gradually: Once confident in the process and positive results are evident (in terms of energy production or soil quality), consider scaling your system to accommodate more waste and produce more biogas.

- Join a Community: Connect with local farmers practicing similar systems. Share tips, challenges, and successes. Many regions have cooperatives or extension services that support renewable energy projects.

12. Looking Toward a Sustainable Future

Every step you take towards converting farm waste into renewable energy and high-quality fertilizer is a step toward a more sustainable future. Here’s why this matters:

- Resilient Farming: In times of rising energy costs and unpredictable supplies, being able to generate your own energy is a major advantage.

- Environmental Stewardship: Reducing greenhouse gas emissions and improving soil health benefits not just your farm, but the local community and the planet as a whole.

- Setting an Example: As one of the many hands working the land, your moves toward sustainability can inspire neighboring farms and future generations to adopt greener practices.

Investing in anaerobic digestion and biomass energy conversion not only improves your quality of life on the farm but also contributes to a legacy of sustainable farming practices.

13. Conclusion

The science behind anaerobic digestion and biomass conversion may sound complex at first, but at its heart, it’s all about nature doing what it does best—breaking down organic material into energy and nutrients. By understanding and harnessing these natural processes, you can turn everyday farm waste into renewable energy and fertilizer. This guide has shown you:

- How anaerobic digestion works in a sealed, oxygen-free environment where microorganisms convert waste into biogas and digestate.

- What biomass is and why every organic material on your farm has the potential to store energy from the sun.

- The simple yet powerful connection between turning waste into energy and improving soil fertility.

- The economic benefits—from lower fuel and fertilizer costs—to the environmental benefits of reducing greenhouse gases and improving your land’s health.

- Practical, step-by-step actions to help you start small, monitor carefully, and eventually scale up your operation with confidence.

Every farm is unique, and the first steps might be small. But with careful planning, regular monitoring, and a willingness to adjust, you can reap the rewards for years to come.

Whether you’re looking to decrease your operating costs, boost your yields with nutrient-rich fertilizer, or simply manage waste more cleanly, turning farm waste into energy through anaerobic digestion and biomass conversion offers a path toward a more self-sufficient and environmentally sound future.

So, take a look around your farm today. Survey your waste, talk to your neighbors, and consider the potential of a pilot project. Your journey to a more resilient, greener future starts with understanding the simple, natural science that’s all around you!

Happy farming, and here’s to making nature work for you!